What if the machines of tomorrow could awaken today transforming how we produce, power, and innovate

Are you ready to shape the future with us?

Welcome to the Industrial Revolution

-

Intelligent Product & Manufacturing Process Design

Conventional products are designed in isolation from the physical realities of manufacturing. Geometry is frozen before tooling variability, material anisotropy, thermal drift, and process noise are understood.

This separation locks inefficiency into the product from day one.

Gotham applies cyber-physical co-design, where product architecture and manufacturing processes are modeled, simulated, and optimized together under real operational constraints.

We fuse CAD, materials science, process physics, and factory telemetry into a unified design space, products emerge already tuned for how they will actually be built.

Multi-Physics Manufacturing Process Intelligence (MP-MPI)

Most factories rely on statistical quality control after deviation occurs. Root causes remain invisible until yield collapses.

Gotham embeds multi-physics intelligence directly into manufacturing processes.

Thermal gradients, force signatures, vibration spectra, electrical load, and material response are sensed and modeled at cycle resolution.

Using online system identification and adaptive control, process parameters self-correct in real time, stabilizing quality, reducing scrap, and eliminating manual retuning.

Constraint-Aware Mass Customization Optimization (CAMCO)

Product variation traditionally fragments production lines, increases inventory, and destabilizes throughput.

Gotham enables mass customization through constraint-aware optimization, where configuration logic, tooling flexibility, process windows, and scheduling are solved as a single optimization problem.

Variant complexity is absorbed mathematically, allowing high-mix, high-volume production without line segmentation or efficiency loss.

Design-for-Disassembly & Circular Manufacturing Intelligence (DfD-CMI)

Most products are not recoverable because disassembly was never engineered.

Gotham integrates design for disassembly intelligence at the component and material level.

Assemblies are structured for deterministic separation, digitally tagged for traceability, and modeled for recovery yield.

Automated classification and disassembly systems reinject materials directly into domestic production transforming end-of-life from waste into feedstock.

Closed-Loop Design–Manufacturing–Recovery Learning Systems (CL-DMRLS)

In legacy manufacturing, knowledge decays between generations.

Gotham builds closed-loop learning systems that connect design intent, manufacturing behavior, field performance, degradation trajectories, and recovery outcomes.

Using continuous model retraining and performance envelope updating, each production cycle improves the next without resetting the system.

Design, production, and recovery evolve as a single intelligence.

-

Adaptive Value Chain Operations

Industrial operations still plan in batches while reality shifts continuously. Maintenance reacts too late, logistics absorb volatility, and production loses synchronization.

Gotham replaces static planning with real-time operational orchestration continuously aligning assets, workforce, logistics, and energy through predictive intelligence.

We deploy physics-aware digital twins fused with live operational telemetry and reinforcement-learning planners that continuously re-optimize decisions as conditions evolve before humans see the deviation.

Human–Machine Symbiotic Systems Engineering (HM-SSE)

Automation often increases complexity instead of performance. Humans are sidelined, systems become brittle, and safety erodes under scale.

Gotham engineers operating models where robotics extend human precision, situational awareness, and safety without removing control.

We design bidirectional control architectures where human intent, machine perception, and robotic actuation co-adapt in real time using cognitive load modeling and closed loop safety envelopes.

Contextualized Extended-Reality Operations Enablement (XR-OE)

Critical decisions fail when operators work blind separated from live system intelligence and physical context.

Gotham embeds real time industrial intelligence directly into the physical workspace, collapsing the gap between data and action.

We spatially anchor live system states, constraints, and predictive alerts using synchronized digital twins, edge compute, and low-latency XR overlays turning the environment itself into an interface.

Adaptive Value Network Dynamics Engineering (AVN-DE)

Modern value chains fracture under disruption because they were never designed as adaptive systems. Single failures cascade. Recovery is slow and costly.

Gotham restructures value chains as self-balancing networks that absorb shocks and reroute capacity automatically.

We apply graph-based system modeling and probabilistic disruption forecasting to continuously simulate alternative flows allowing the network to rebalance before constraints become losses.

Continuous Lifecycle Systems Optimization (CLSO)

Most industrial systems stagnate after deployment. Performance decays, costs rise, and improvement becomes episodic.

Gotham embeds continuous optimization across assets, operations, and energy systems so performance compounds over time.

We close the loop between design, field data, degradation modeling, and operational feedback allowing every cycle of use to retrain system behavior and update performance envelopes automatically.

-

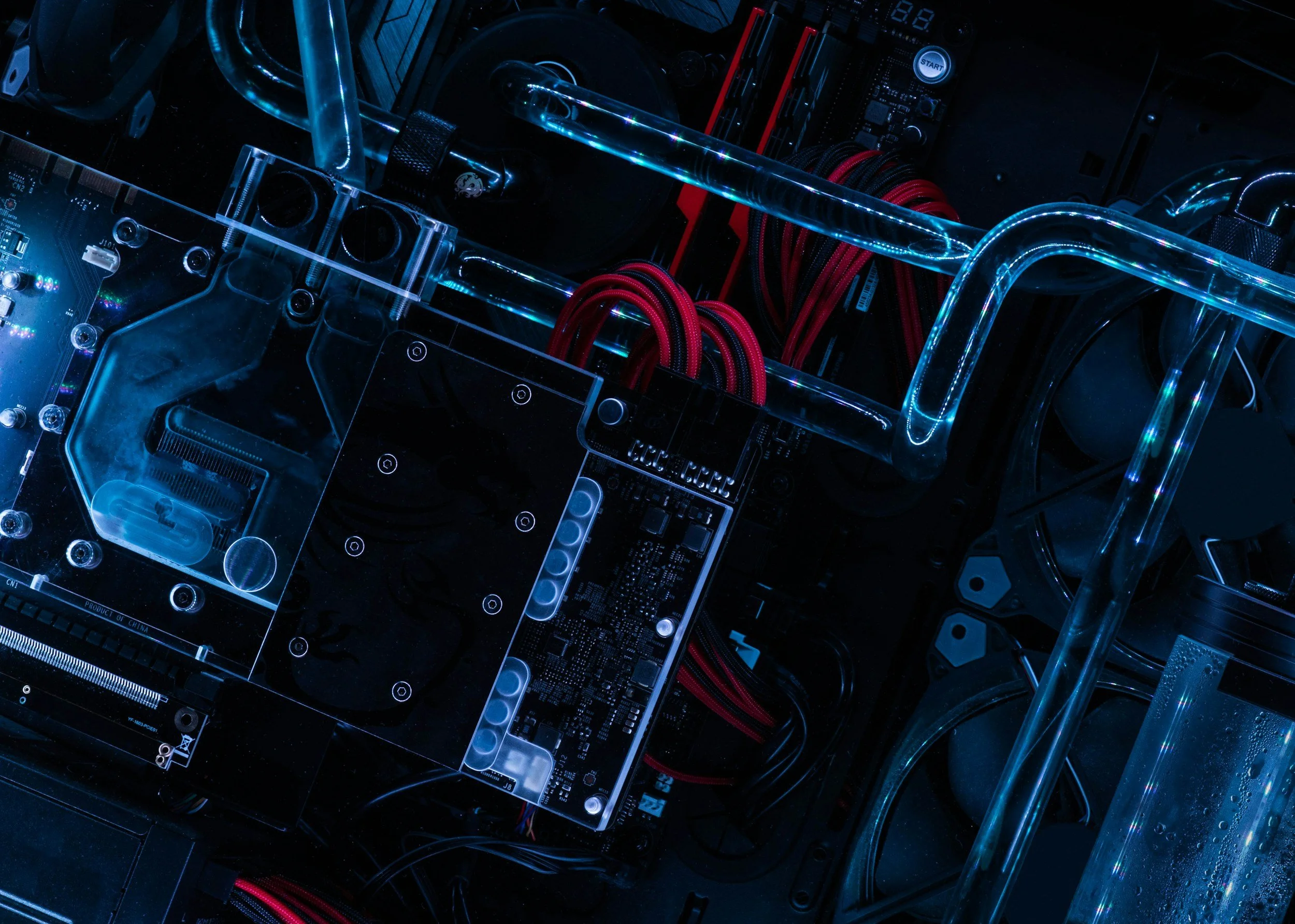

Data Exchange & Processing Platform Design

Modern industrial systems generate high-frequency, high-dimensional data, yet most architectures treat it as asynchronous information rather than a control signal.

Variable latency, non-deterministic routing, and centralized bottlenecks break feedback loops between sensing, computation, and actuation, forcing operations into reactive modes.

Gotham will engineer with you deterministic cyber-physical data fabrics where data movement, timing, and integrity are co-designed with the physical processes they control.

Information flows with bounded latency, known jitter, and guaranteed delivery allowing digital intelligence to directly govern physical behavior.

Time-Sensitive Networking & Software-Defined Control Planes (TSN-SDCP)

Industrial control systems fail when communication delays exceed process tolerance.

Gotham deploys time-sensitive networking (TSN) combined with software-defined control planes that enforce deterministic scheduling, traffic isolation, and priority arbitration across distributed sites.

Network behavior is mathematically constrained, not statistically inferred ensuring control packets, sensor streams, and safety signals arrive within strict temporal bounds.

The network becomes part of the control system, not an external dependency.

Federated Learning & Distributed Model Consensus Systems (FL-DMCS)

Centralized machine learning architectures struggle with scale, privacy, and domain specialization.

Gotham implements federated learning frameworks with distributed model consensus, enabling local systems to train on-site while contributing to global intelligence through encrypted parameter exchange.

Models evolve collectively without raw data migration preserving sovereignty, reducing bandwidth pressure, and accelerating learning across heterogeneous environments.

American knowledge compounds without central fragility.

Hierarchical Edge–Cloud Computational Stratification (HECCS)

Real time control and long horizon optimization impose fundamentally different computational constraints.

Gotham designs hierarchical computational stratification, where edge systems execute low-latency inference, anomaly detection, and control-loop closure, while cloud systems perform global optimization, simulation, and model evolution.

Temporal separation of computation ensures immediate physical response without sacrificing strategic intelligence.

Decisions occur at the correct time scale by design.

Zero-Trust Cryptographic Interoperability & Identity Engineering (ZT-CIIE)

As industrial ecosystems expand, trust assumptions collapse.

Gotham applies zero trust security models with cryptographic identity, hardware-rooted attestation, and policy based access enforcement across every node and transaction.

Interoperability is achieved through verifiable trust, not perimeter defense allowing American partners, suppliers, and operators to integrate without exposing critical systems.

Engineering cybersecurity into our systems gives America the chance to innovate without having to compromise by outsourcing services that we only previously international.